Cast Iron Surface Plates

- Graph Datum

- Products

- Cast Iron Surface Plates

Click / Drag To Spin

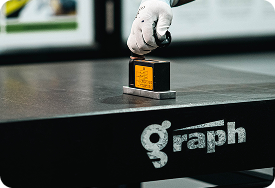

Cast Iron Surface Plate Manufacturers

Our cast iron surface plates are engineered for - high-load applications and long-term dimensional stability. As a trusted cast iron inspection table supplier, we offer robust solutions tailored for industrial-grade precision.

These bench type surface plates cast iron models, are ideal for demanding environments where accuracy and durability are highly needed.

Whether you are sourcing a surface plate for inspection in India or globally - we provide reliable solutions tailored to your needs. If you are seeking specialized equipment for component validation, our products are engineered for precision. All our offerings meet the stringent requirements of quality control and manufacturing excellence.

Significant Features of Industrial Cast Iron Plates

As a cast iron inspection table supplier, we deliver IS standard cast iron surface plates, rust-resistant cast iron surface plates, and precision cast iron measuring plates. Our industrial cast iron plates meet the modern quality control requirements.

Flatness

Cast iron plates are available in multiple grades with flatness tolerances depending on size and standards.

Surface Finish

Top surfaces of cast iron plates are precision-machined to achieve high accuracy and repeatability.

Higher Capacity

They are perfect for heavy-duty applications such as tool setup, inspection, and layout marking.

Vibration Damping

They naturally absorb mechanical vibrations. So, they are suitable for CNC inspection and metrology tasks.

Available Cast Iron Plate Sizes

Graph Datum provides a wide-ranging series of cast iron surface plate with T slots and cast iron plate for calibration labs with sizes to suit several industrial and inspection demands -

Custom Sizes Available

We manufacture tailor-made surface plates to meet specific customer requirements — both in dimension and grade.

Different Types of Cast Iron Surface Plates

Standard Flat Surface Plates

- Leveraged for general inspection, layout marking, and tool setup.

- Offers hand-scraped or precision-machined top surface.

T-Slotted Surface Plates

- Used for Mounting fixtures, jigs, and bench centers.

- Offers integrated T-slots for clamping and positioning components.

Surface Plates with Bench Center Attachments

- Utilized for precision alignment and concentricity checks.

- Offers T-slots combined with bench center mounts for rotating parts inspection.

Substantial Cast Iron Surface Plate Applications

Cast Iron surface plates play a highly crucial role in many industrial and metrology inspection applications, including -

Precision Inspection

Used as a reference base for checking flatness, squareness, and parallelism.

Tool Making and Machining

Serves as a stable platform for aligning jigs, fixtures, and tooling setups.

Gauge Calibration

Ensure accuracy in metrology labs and quality control departments.

Heavy-Duty Industrial Use

Supports inspection of large elements in the automotive, aerospace, and heavy engineering industry sectors.

As cast iron surface plate manufacturers, our products serve as reliable surface flatness testing plates. These plates function as metrology cast iron reference tools and offer long-term stability and repeatability for quality control labs.

Frequently Asked Questions

We understand precision in manufacturing matters, and so does all-inclusive clarity. Here are the extensive answers to enquiries we obtain from our prospects and clients.

01. What is the precision and accuracy tolerance of your cast iron surface plates?

The precision and accuracy tolerance of cast iron surface plates depends on their grade and intended application. As per standards followed in India – cast iron surface plates are classified into diverse grades, with each offering varying levels of flatness tolerance.

02. How frequently should cast iron surface plates be calibrated?

The recommended calibration frequency for cast iron surface plates depends on usage intensity, environmental conditions, and quality assurance requirements.

03. Can I get a customized size or shape of cast iron surface plates?

Yes, you can absolutely get custom sizes and shapes of cast iron surface plates. At Graph Datum, our teams deliver products tailored to your specific dimensional, load-bearing, and metrology requirements.

04. Do you ship cast iron surface plates globally?

Yes, at Graph Datum, we consistently ship cast iron surface plates globally. We ship ready cast iron surface plates, including custom sizes and configurations. These plates are manufactured to match international standards and are securely packed for export to different regions.