Granite Surface Plates

- Graph Datum

- Products

- Granite Surface Plates

Click / Drag To Spin

Granite Surface Plate Manufacturers

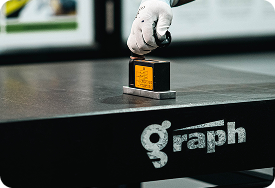

Granite Surface Plates are precision tools utilised across manufacturing, aerospace, metrology, automotive, and quality control environments. They provide a flat and stable reference surface for inspection, measurement, and layout tasks.

With a strong presence in the supply of granite metrology equipment in India, we provide solutions for laboratories, manufacturing units, and calibration facilities seeking durable reference surfaces for dimensional inspection. Our high precision granite measuring plates are crafted for extreme flatness and stability.

Significant Features of Granite Surface Plates

As a black granite surface plate supplier, we deliver IS 7327 granite surface plates adhering to global standards. We specialize in providing inspection grade and NABL certified granite plates that meet the modern quality control demands.

Flatness

Granite surface plates maintain extreme precision and are measured in microns for accurate measurements.

Surface Finish

Offer exceptional vibration absorption – reducing measurement errors caused by diverse environmental factors.

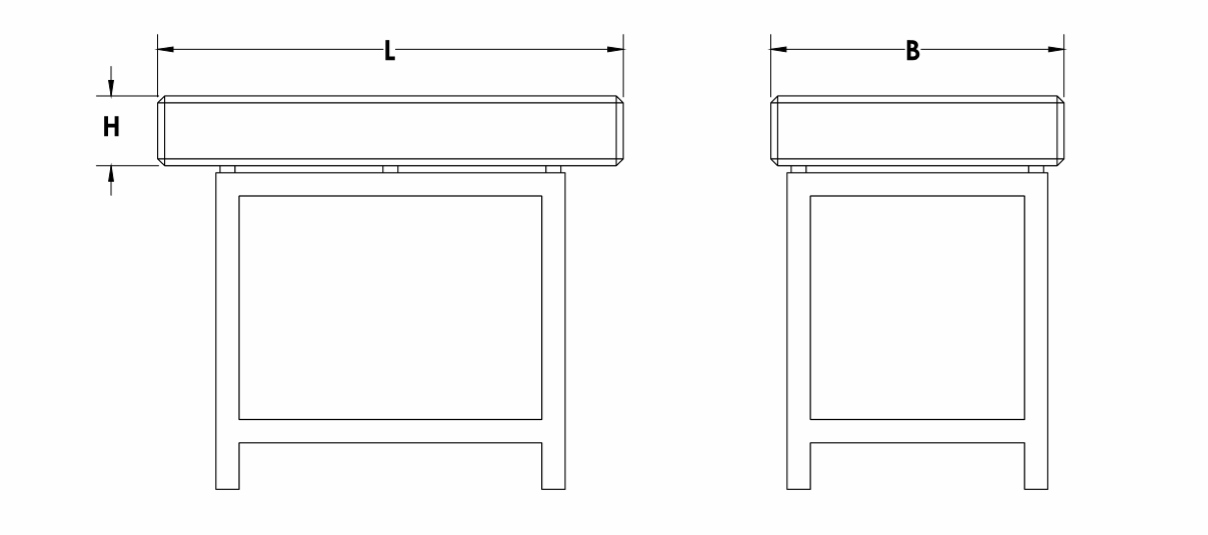

Thickness

Granite surface plates resist rust and corrosion. This scenario makes it suitable for both indoor and outdoor applications.

Hardness

Resistant to most oils, solvents, and clearing agents. This scenario ensures longevity and safeguards from damage.

Available Granite Surface Plate Sizes

Graph Datum provides an extensive series of standard and custom granite surface plate in Pune with sizes to suit several industrial and inspection needs -

Custom Sizes Available

We manufacture tailor-made surface plates to meet specific customer requirements — both in dimension and grade.

Diverse Types of Granite Surface Plates

Standard Grade Granite Surface Plates

- Leveraged for general industrial applications.

- Delivers needed flatness and explicit stability for measuring tasks.

High-Grade Granite Surface Plates

- Precisely designed for precision and high-accuracy environments.

- Provides ultra-flatness and excellent surface finish for critical measurements.

Inspection Grade Granite Surface Plates

- Calibrated for supreme flatness, uniformity, and smoothness.

- Best used for laboratory and metrology settings requiring the highest accuracy.

Comparison Table (Granite vs. Other Materials)

Granite surface plates outperform cast iron in almost all critical metrics and categories linked to precision, stability, and durability. This makes them the best choice for higher accuracy inspection and metrology.

| Feature | Granite Surface Plate | Cast Iron Plate |

|---|---|---|

| Flatness | High Precision (microns) | Lower |

| Hardness | Highly wear-resistant | Moderate |

| Non-Corrosive | Rust & corrosion-proof | Rusts over time |

| Thermal Stability | Minimal expansion | Moderate |

| Vibration Damping | Excellent | Moderate |

| Chemical Resistance | Resistant to oils & solvents | Can be damaged |

Substantial Granite Surface Plate Applications

Granite surface plates play a highly critical role in several industrial and metrology inspection applications, comprising –

Precision Inspection

Ensuring accuracy in metrology labs

Tool Alignment

Helping in CNC machining & tool setup

Gauge Calibration

Reliable reference for measuring instruments

Measuring Tools

Providing a stable base for precision assembly

As black granite surface plate manufacturers and suppliers, we offer unparalleled precision, steadiness, and resilience across our products. So, that they stay significant tools for quality assurance and metrology applications across several industrial sectors.

Frequently Asked Questions

We understand precision in manufacturing matters, and so does comprehensive clarity. Here are the considerable answers to enquiries we receive from our prospects and clientele.

01. What is the precision and accuracy tolerance of your granite surface plates?

Industrial surface plates for QA are classified by flatness tolerance grades defined in standards like IS 7327. These tolerance levels ensure that the granite surface plates provide a reliable reference surface for – dimensional inspection and calibration.

02. How frequently should granite surface plates be calibrated?

The ideal calibration interval for granite surface plates depends on several factors—including usage intensity, environmental conditions, and the level of precision required. For high-accuracy plates such as Grade 00 and Grade 0 (as per IS 7327 and DIN 876), more frequent calibration is recommended to maintain their certified flatness and repeatability.

03. Can I get a custom size or shape of granite surface plates?

Yes, you can absolutely get custom sizes and shapes of granite surface plate with levelling jacks. Manufacturers like Graph Datum offer extensive customization options, comprising customization capabilities.

04. Do you ship granite surface plates globally?

Yes, laboratory-grade granite surface plates can be shipped globally. Manufacturers like Graph Datum offer global shipping for both standard and custom flatness calibrated surface plates.